Getting the control they want in Danville, Kentucky

Danville, Kentucky, is known as the City of Firsts. The City built the first courthouse in Kentucky, the first Kentucky constitution was written and signed there, they had the first U.S. post office west of the Allegheny Mountains, Ephraim McDowell completed the first known successful laparotomy there in 1809, and Danville was the first capital of Kentucky! This profile describes the implementation of a new SCADA control system completed by VTScada Certified Advanced Integrator, Rawdon Myers, Inc.

Danville’s municipal water and sewer system consists of four individual departments: filtration, water distribution, wastewater rehabilitation, and treatment. The department operates one water filtration plant, two wastewater treatment plants, over 15 pump and lift stations; and maintains over 400 miles of water and sewer lines that serve more than 11,200 customers and provides water to four water districts. In addition, sanitary wastewater is separated into water to be released into the natural water system and a treatment by-product that is used for fertilization on the City farm.

Danville’s municipal water and sewer system consists of four individual departments: filtration, water distribution, wastewater rehabilitation, and treatment. The department operates one water filtration plant, two wastewater treatment plants, over 15 pump and lift stations; and maintains over 400 miles of water and sewer lines that serve more than 11,200 customers and provides water to four water districts. In addition, sanitary wastewater is separated into water to be released into the natural water system and a treatment by-product that is used for fertilization on the City farm.

Chris Gregory, Project Engineer at Rawdon Myers states “The customer was building a new plant and needed a SCADA system that would give them the control they wanted.” They chose VTScada as the solution. The Danville plant staff was an integral part of the design and implementation of the new SCADA system.

Project History – In 2013, Danville elected to increase the capacity of its water treatment plant from 8 MGD to 12 MGD and add a Granular Activated Carbon (GAC) supplementary filtration system. During the complex expansion, the plant needed to remain 100% operational. This $30 million, multiple-year project was not an ordinary undertaking.

Prior to construction, each phase – filter building, settling tanks, raw water, GAC and chemical – had to be completed and tested to verify that the system would be functional and able to achieve its target objective.

Prior to construction, the complete SCADA system had to be completed – panels made and tested to verify that it would be functional and able to achieve its target objective.

As the systems integrator for this five-phase project – filter building, settling tanks, raw water, GAC and chemical – Rawdon Myers’ first step; a most critical one was to create a strategy that addressed the intricate, multifaceted components. Each individual facet was like a puzzle piece and all of them needed to fit together perfectly. Layout of the entire system was done off site and the owner, engineers and plant operators all witnessed the Factory Acceptance Test (FAT). The added challenge of keeping the plant running at full capacity required meticulous planning to align with the construction schedule.

In addition to the fundamental determinations for a systems integration – scope, number of computers needed, panel layout, panel PCs and more – the project involved a considerable number of components: coordination of other manufacturers’ equipment to be integrated into the system, programming unique to each element and precise scheduling to avoid interference with plant operation.

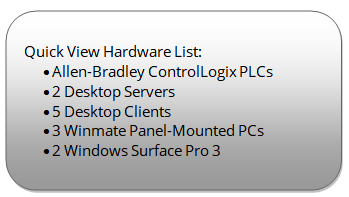

At completion of the project in July 2017, the Danville Water Treatment Plant has a control system with the functionality to run the plant in fully automatic mode, from beginning to end. Capacity has increased by 50% and filtration is augmented by a GAC system. Wireless access enables the use of tablets throughout the plant. The HMI can be viewed from multiple sources – two servers, five workstations, three panel PCs and two tablets.

“VTScada was helpful since easy deployment was critical to me.” Gregory states. He continues “they have numerous devices that they want to view the HMI on. Server redundancy was also very important. It’s a large tag count project so protecting the data was important as well. The finished system gives them the control we set out for at the beginning of the project.”

“Support was critical in the design of the project. Along with Trihedral’s help, I reduced development time by using parameterized pages and widgets.” Gregory explains. “The owner sent an employee to the included training class about halfway through the project. This individual came back with a much better understanding of how the system works and how it can be maintained going forward.”

Rawdon Myers, Inc. – For municipal projects of any size, RMI provides water and wastewater solutions that bring efficiency and reliability. They offer design, digital telemetry and PLC/HMI-based SCADA systems, systems startup and technical support. With more than 1,500 instrumentation and control systems successfully furnished, Rawdon Myers brings proven stability to your project. RMI’s system engineers and service technicians represent a combined 100+ years of experience. RMI brings expertise and unmatched service to owners, engineers and contractors in Ohio, Kentucky, Indiana, and Western Pennsylvania.

| Try It For Yourself Download the 90-day Trial |

For More Details: Chris Gregory, 513-965-5300 info@rawdonmyers.com |