Alflex Technologies is a VTScada Certified Solution Provider located in the Netherlands. They work closely with a world leader in Impressed Current Cathodic Protection (ICCP) to provide a variety of anti-corrosion solutions and products for various kinds of steel structures such as wind farms, ships, and oil platforms to keep them running effectively. ICCP systems are commonly used at sea or in other settings where environmental conditions make it challenging to communicate with structures to read data and perform process control.

Watch the Video Case study update from 2022:

“The complete SCADA application is made and tested using emulator software and modules,” says Luxen. “We build a small setup connected to emulators that simulate the sensors and power supplies of the ICCP system. This allows us to test all the turbines by setting different values and generating alarms.” After approval, the team installs the system on a server connected to the offshore park. “We’ll then do a quick scan to see if the turbines show the right values. The settings of the ICCP systems sometimes are not entered correctly. We can change that using VTScada.”

Martin Luxen is a Technical Sales Engineer with Alflex. He provides sales and technical advice for thermal solutions and is responsible for programming their anti-corrosion SCADA systems. Luxen describes below the customized SCADA solution that Alflex developed using VTScada software from Trihedral that allows their customers to easily monitor and control their remote assets.

The Software Selection Process

Before discovering VTScada on Google, Alflex was struggling with a software product called Lookout by National Instruments. “We’ve had update problems for newer versions of Windows. Lookout did not have good maintenance of the software and seldom fixed any bugs. Besides that, the software looked very outdated. It looked very Windows XP.”

When searching for a new SCADA product Luxen says, “We tried a couple of HMI/SCADA packages. VTScada was simply the most convenient software to work with and had a good interface which was one of the main focuses in our selection process.

The Importance of “Ease-of-Use”

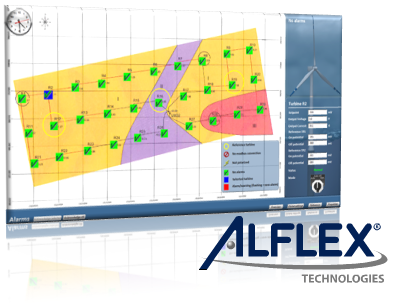

“We were also able to learn the product without taking training.” VTScada’s ease-of-use tools improve efficiency by allowing them to design and implement SCADA packages in a short time. “The time spent on each project has decreased tremendously because of the easy way the software allows you to copy tags and create your own widgets.” Luxen points out that the new software allows them to do some things easier than they ever could. “We can monitor the status of the systems offshore and connect all systems to an external overall SCADA plan; however, with VTScada it is much easier to implement!”

The New Project Design Process

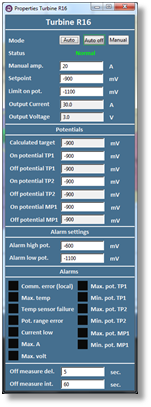

To help model complex objects that have almost identical elements, VTScada supports hierarchical parent tags that include multiple child tags. For example, Alflex can create a parent tag that represents a typical wind turbine in a customer’s wind farm. “During the design process I implement all the variables I want to monitor, and I use that to create an “ICCP template,” says Luxen. “Each wind turbine has a similar ICCP system so I can copy each system and simply change the names and IP-addresses. After making the templates, I focus on the Graphical User interface (GUI) which includes a grid of the turbine park and turbines that users can click on. The main screen shows the most important values and alarms (if applicable). Advanced properties are shown on a different page.”

SCADA System Testing

The Completed Systems

“The ICCP systems work stand-alone on the turbines,” explains Luxen. “The SCADA application checks the status of the systems and sees any alarms. If necessary, settings can be changed. In an alarm situation, settings can be altered to suppress the alarms. VTScada Historical Data Viewer (HDV) displays the polarization state of the turbine foundation.” When a foundation is “polarized,” it is protected against corrosion as much as possible thanks to the ICCP system.”

Notable Installations to Date

“We have already successfully deployed VTScada for several customers in different markets; offshore, shipping and food industry to name a few,” says Luxen. “We made a SCADA system for a naval project that was not only for monitoring, but was also active,” says Luxen. “The system plays a key role in driving the ICCP systems where normally they work stand-alone. This took some extensive programming within the tags of VTScada as well as special considerations in case of a computer failure or restarts.”

Expanding Into Other SCADA Markets

Now that they have developed a standardized ICCP SCADA product that they can trust and easily deploy, Alflex plans to expand into other markets where SCADA is used. Says Luxen, “If you have an increasing need for monitoring, reporting and alerting of your critical business processes, then we would like you to look at the possibilities that VTScada software can provide.”

About Alflex

Since 1991, Alflex Technologies has built a broad portfolio of innovative and effective solutions in the fields of electronics, thermodynamic systems, process control, and measurement for a variety of industries including medical, manufacturing, and automotive. Their Thermal Division provides solutions such as temperature regulation, heating (foil heaters) and cooling (peltier cooling) while their Electronics Division designs electronics from scratch in-house and writes embedded software for the microcontrollers and PC-software when needed. All are built on customer request.

More Details

Martin Luxen: +31 (0)79 362 00 00

www.alflex-technologies.com