Completed By Advanced-Certified Integrator, Enterprise Automation

A large mechanical mollusk has finally found its home in Upper Newport Bay, where it protects the sensitive regional habitat by raking up the trash flowing downstream from the San Diego Creek and funneling it into collection bins.

The $5.5 million trash interceptor is designed to reduce the amount of floating waste entering the Upper Newport Bay via San Diego Creek by 80%, representing an anticipated 240 tons annually.

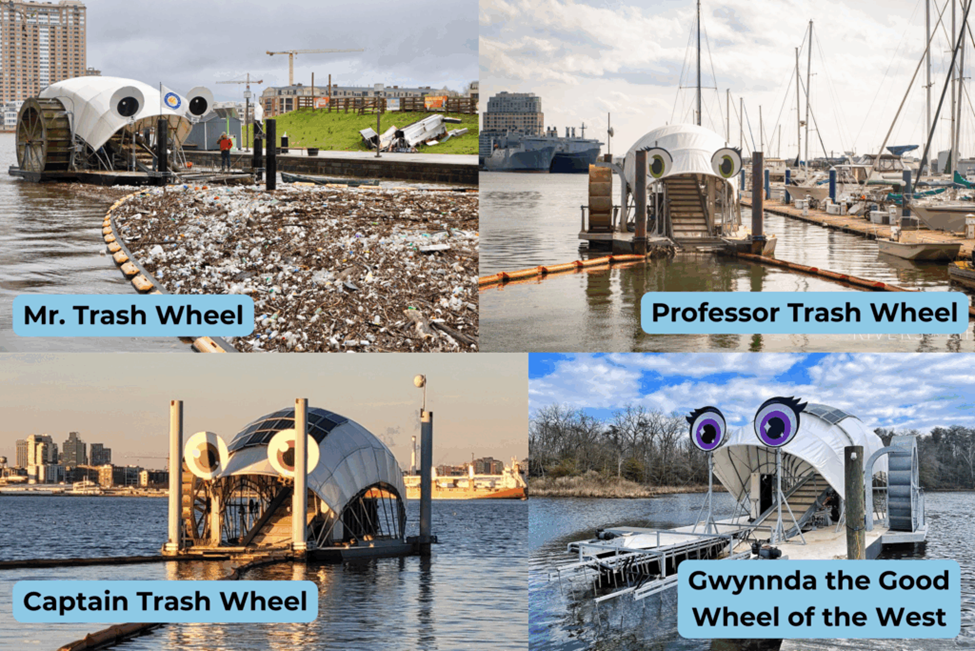

Their famed googly-eyed counterparts in Baltimore have collected over 2300 tons of trash collectively since the first Mr. Trash Wheel installation in 2014.

The original Trash Wheel family is comprised of:

- Mr. Trash Wheel

- Professor Trash Wheel

- Captain Trash Wheel

- Gwynnda the Good Wheel of the West

These siblings operate semi-autonomously and have inspired trash interceptor innovation around the world. In fact, the Newport Beach trash wheel is the first trash wheel in the US to be automated by SCADA and PLCs. A big part of our job was bringing that automation to life. The scope encompassed not only setting up the SCADA software and control functions, but also electrical design, PLC programming, testing, and commissioning. The essential control functions of the trash wheel manage the pumps that power the wheel, operate the conveyor belt system that transports the trash from the river to the collection bins, and monitor the operation of the bins. The bins must be easily accessed by trash collectors, who are responsible for emptying them into garbage trucks for proper disposal.

The various signals, inputs, and outputs cover a range of maintenance and protective measures, such as monitoring the battery levels of the rooftop solar panels that power the trash wheel and its associated equipment. The system also monitors critical parameters such as river level and site temperature. When there are risky environmental conditions or adverse weather, these functions exist to prevent damage to the system. For example, pumps are set to stop operating when the river level is too high.

The City of Newport Beach opted to have the trash wheel’s SCADA system operate independently of the city’s main SCADA system. This was so they could use this site as a test for VTScada in the case that they migrate other sites to the platform. Among our suggestions, VTScada stood out for its modern capabilities and the comparative ease of setting it up.

While the City’s utilities operators are expected to be the primary users of the system, the trash wheel is more publicly-accessible compared to our typical factory automation projects and would attract attention from local officials such as the mayor of Newport Beach. The engineers took an approach that struck a balance between visual appeal and operational efficiency. They borrowed principles of high-performance graphics to establish a standardized design for the user interface, design pages for the new system, and even include playful animated touches.

The design philosophy included using color schemes to convey operational status (for example, red for alarms and green for normal operation). Against a monochromatic color scheme, the operational status and critical information are more obvious and visible. We designed the standards of this project to serve as a starting point for future projects.

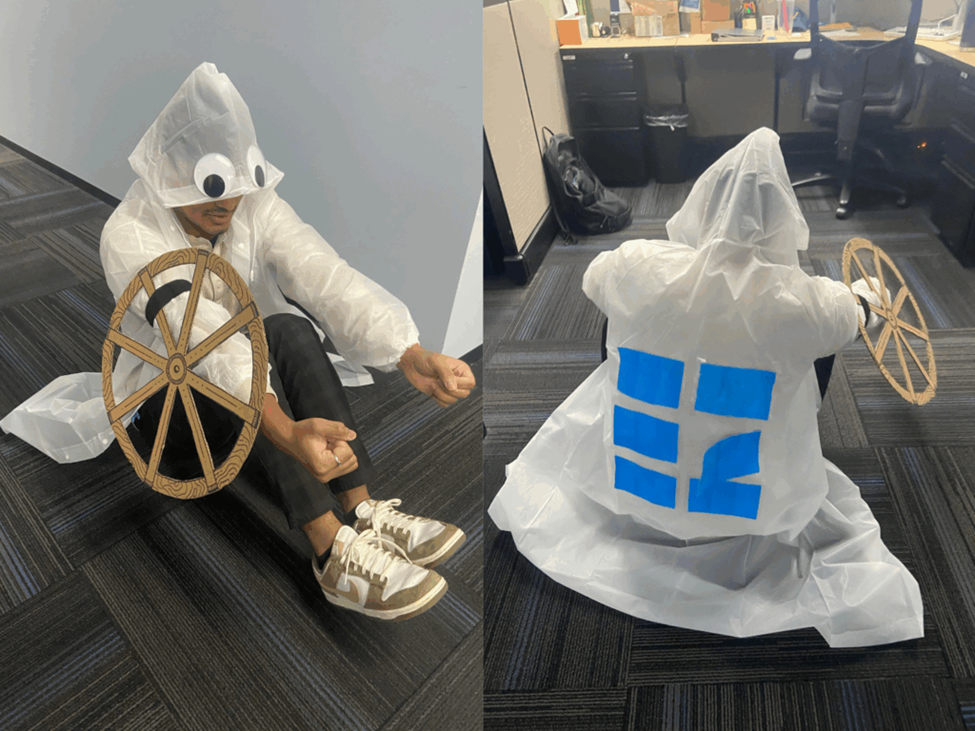

During factory acceptance testing, our client appreciated the usability and effectiveness of the newly designed screens and expressed interest in leveraging these standards in future projects. Within our own office, the opening of the trash wheel has been a highly anticipated event, in large part thanks to the enthusiasm of our project team. When one engineering lead, Avinash Laha, dressed up as the trash wheel for Halloween 2024, we all got all on board as members of the Newport Beach trash wheel’s fan club. If any cities are interested in commissioning their own automated trash interceptors, contact us. We have an expert team and googly eye animations ready.

Case Study Originally published by Enterprise Automation: Meet the first automated trash wheel in Newport Beach

About EA:

From consulting and planning to execution and deployment, Enterprise Automation provides systems integration and automation services for process-driven industries. With dedicated offices in California and Arizona and over 500 additional Tetra Tech offices around the globe, Enterprise Automation commands best-in-class engineering services and disciplines to facilitate specialized turnkey and design build automation projects. In 2025, we became a leading member of Tetra Tech’s Digital Systems Group (DSX), which connects clients with their assets through integrated control and digital systems. This unit addresses water, infrastructure, energy, and manufacturing challenges, helping clients modernize operations and enhance asset visibility. Through our DSX partners TIGA, Convergence Controls, and SAGE Group, our clients benefit from this network of highly-vetted digital transformation groups across the globe and further bridge the gap between operations and enterprise systems. These multidisciplinary teams offer a full spectrum of services, from electrical and instrumentation and control (I&C) design to enterprise SCADA, cybersecurity, and cloud integration.