Case Study with VTScada Partner: Electric Supply Source

Overview

South Georgia Pecan, a leading pecan processor, recently implemented a Phase 1 pasteurization process at its Horizon City, Texas facility. This critical step ensures pecans are sanitized, preheated, and free of harmful bacteria before moving to subsequent stages of production. The company partnered with ESS and VTScada to deliver a robust, flexible control system capable of managing complex operations and diverse hardware.

The Challenge

The plant needed a solution to:

- Control the initial pasteurization process.

- Integrate multiple PLC brands across different stages.

- Provide detailed temperature reporting for compliance and quality assurance.

- Enable future scalability for additional phases like cracking, sorting, and packaging.

The Process

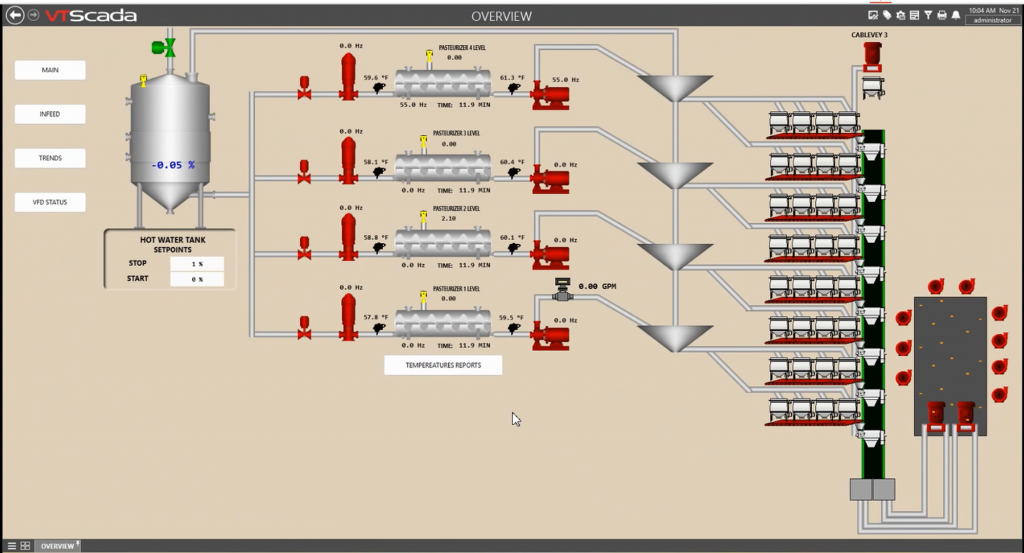

Phase 1: Pasteurization

- Pecans are sorted by size (round, oval, small, large).

- After weighing, they move through conveyors for gradual preheating to 180°F minimum.

- This step removes dust and kills bacteria, ensuring food safety.

Infeed System

- Transfers pecans from silos while maintaining level control.

- Tracks rate (lbs/hour), batching, and totalized weight.

Why VTScada?

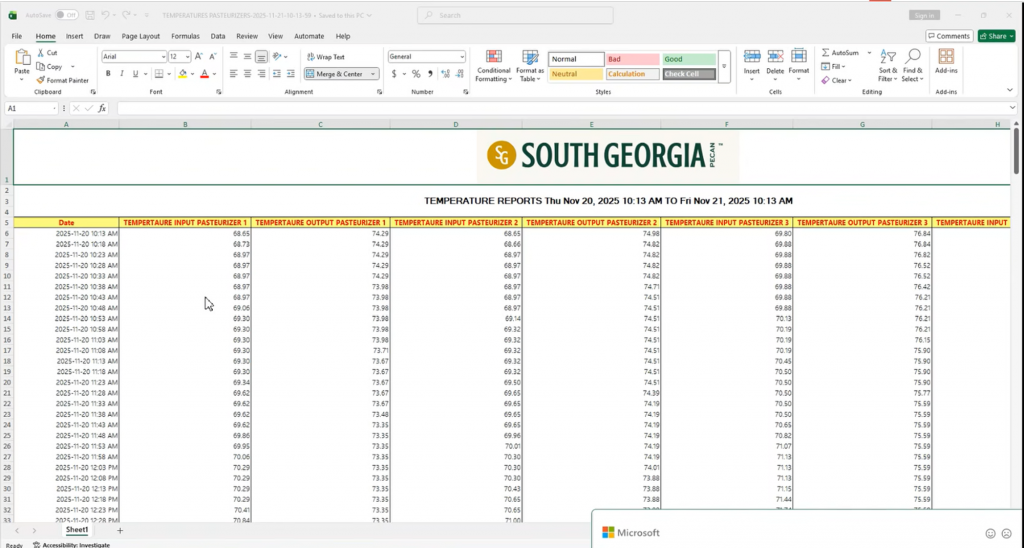

Temperature reporting was the deciding factor. VTScada provides:

- Historical data for 1-day, 1-week, and 1-month intervals.

- Seamless integration with a mix of PLC hardware, including:

- Siemens S7-1200 (pasteurization and crackers)

- Allen-Bradley (sorting)

- Automation Direct & IDEX (packaging)

This flexibility ensures smooth communication across all systems, reducing complexity and improving reliability.

Implementation

ESS installed a process from Rochim (Mexico) and built custom control panels for the first phase. With VTScada, operators can monitor and control every aspect of pasteurization, from infeed to temperature tracking.

Results

- Improved efficiency: Operators have real-time visibility and historical insights.

- Enhanced compliance: Accurate temperature logs meet food safety standards.

- Operator satisfaction: “Makes life happier for them!”

Future Plans

- Immediate goal: Implement batching reports by shift.

- Next phases:

- Cracking: Shell removal, vision system for quality control (color, dryness).

- Sorting & Packaging: 5 lb bags for customers like Flagstone (candies, salted snacks).

- Boilers: Additional units integrated into VTScada.

Key Takeaways

South Georgia Pecan’s adoption of VTScada demonstrates how a flexible SCADA platform can unify diverse hardware, streamline operations, and prepare for future growth—all while ensuring food safety and quality.

About Electric Supply Source:

For over 20 years, Electric Supply Source (ESS) has been a trusted leader in industrial automation, power distribution, and control systems. Based in El Paso County and Southern New Mexico, we specialize in SCADA integration, PLC programming, fiber optic solutions, and UL 508A panel fabrication, serving industries such as manufacturing, utilities, oil & gas, and infrastructure.

At ESS, we engineer efficiency, helping businesses streamline operations, enhance reliability, and improve system performance. Our team of certified experts delivers custom-tailored solutions that meet the highest industry standards, ensuring safety, compliance, and long-term value.

From automation and electrical infrastructure to high-speed networking and energy management, ESS is powering industry and enabling innovation.