SCADA Dreams and Realities

Every time a business or utility completes a new Supervisory Control and Data Acquisition (SCADA) system, their secret dream is that it will work flawlessly forever. In reality, the average system has an effective lifespan of about ten years. While some software manufacturers support their products well beyond this timeframe, others abruptly abandon product lines leaving users no choice but to start over with a different product. Other systems are replaced because they never worked quite as well as hoped. Replacing an existing system can present opportunities that are unavailable when building a SCADA system from scratch. This article outlines four concepts, or pillars, to support your search for new SCADA software that will help you build on the value of your existing system and grow with your changing needs well into the future.

4 Pillars for Choosing New SCADA Software

What is SCADA?

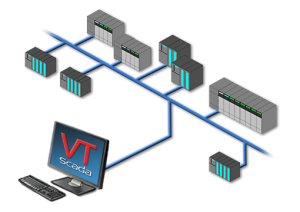

The term SCADA often means different things to different users. Some think of it as Programmable Logic Controllers (PLCs), Remote Telemetry Units (RTUs), and their ladder logic. For others, it’s a reporting package or a web app that presents data from networked devices. Though every system is different, most share the following elements:

- One or more monitoring and control devices to log process data and control equipment (e.g., PLCs and RTUs)

- A communication network to send commands and return process data

- Human Machine Interface (HMI) software to graphically represent this data

- A database of I/O points (tags) that define the objects in the system

- An alarm management system to alert users to problems

- A database of historical process information logged by the system

- Trends and reporting tools to derive insight from historical data

Pillar #1 – Hang on to Your Control Devices

Typically, the most expensive components of a SCADA system is the network of monitoring and control devices. In addition to the cost of the hardware, there is also the cost of installation, programming and testing. During a SCADA conversion, reusing this equipment presents an opportunity for significant savings.

SCADA software communicates with control devices via software protocols. The best approach is to select software that supports many protocols through a library of direct protocol drivers, offering flexibility to support the devices you currently have, and others you may prefer in the future.

Where direct drivers are unavailable, OLE for Process Control (OPC) uses a separate software to translate between the control device and the SCADA software. This solution is acceptable but limits the ability to adjust polling rates during critical situations, and does not allow the SCADA software direct access to the communications link for diagnostics. Be especially careful if your devices use non-standard (aka. proprietary) communication protocols. Some software products also include direct drivers for these kinds of devices.

Pillar #2 – Convert Your Tags, Don’t Recreate Them

Tags are software representations of system variables, typically describing inputs such as field measurements and alarm status; and outputs, such as control actions and setpoints. Systems can include anywhere from just a few tags to a few million. For example, Miami-Dade Water and Sewer Authority’s recent SCADA upgrade required conversion of approximately 236,000 tags. Consider that each tag must be read from the existing system, entered in the new system and then re-commissioned to validate functionality. Recreating tags in a new SCADA system can be correspondingly time consuming and costly.

Automatic conversion utilities can eliminate the potential for manual mistakes and reduce conversion time to minutes rather than hours or days. Some software products offer such automated conversion utilities and services, typically converting common tag types that exist in both software packages.

Keep in mind that tag conversions are not perfect as they must account for differences in tag parameters used by each SCADA software, such as protocol addressing, script tags, mathematical expressions, and naming conventions. Consult the software provider to determine if it supports converting from your existing tag database.

Pillar #3 – When to Convert Historical Data

If having access to your existing historical data is important, you may want to consider converting the data in your Historian to the new SCADA platform. Indeed, this may be essential if the data is required for regulatory reporting, preventive maintenance, or comparative data analysis.

In the case of one oil and gas well monitoring application, regulatory commitments required the data to be available for 10 years for auditing purposes. The existing data was imported into the new SCADA Historian, allowing data views to include both legacy and real-time data. Be sure to ask the software manufacturers or your Systems Integrator if they are able to offer this kind of service.

Pillar #4 – Graphical Displays Aren’t What They Used to Be

Nor should they be. When considering conversion of an application, many users ask about converting their displays in order to save time and avoid operator confusion when converting to a new SCADA product. However, your existing display pages most likely represent a vision of the process as it existed when the application was first created, with adjustments made over the years as functionality evolved.

If the displays were to be converted as is, you may end up spending money on a new application that looks as dated and disorganized as the one you just replaced.

Instead, consider that the conversion process offers a chance to standardize, enhance, and reorganize. This need not be a drastic departure from the current system; rather it represents the opportunity to optimize the operators’ experience and reflect their current needs and priorities.

Today’s SCADA graphical development tools have come a long way. Not only do they look better, they are easier to develop. In most cases, rebuilding screens is a better use of your resources.

Ten Years and Beyond!

These pillars are not simply intended to cut the cost of updating your aging SCADA system, they are meant to steer you toward a solution that will continue to grow with you far beyond the typical ten year lifecycle.