Project Completed by Central Texas Water Maintenance (CTWM)

Serving a suburb of the Greater Austin Metropolitan Area, Dripping Springs Water Supply Corporation (DSWSC) recently decided to replace their Wonderware and WIN-911 SCADA system with VTScada, with the help of Austin area integrator, Central Texas Water Maintenance (CTWM).

Serving a suburb of the Greater Austin Metropolitan Area, Dripping Springs Water Supply Corporation (DSWSC) recently decided to replace their Wonderware and WIN-911 SCADA system with VTScada, with the help of Austin area integrator, Central Texas Water Maintenance (CTWM).

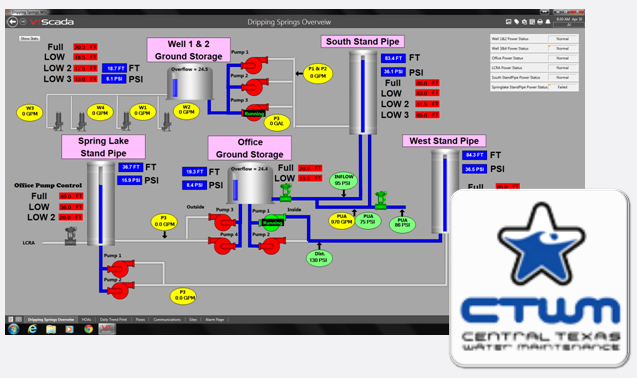

The Dripping Springs Water Supply Corporation System: DSWSC began with its first water well in 1964; it now operates four well sites that can produce up to 1.5 million gallons per day, three pump stations and a surface water connection site. It has more than 900,000 gallons of water storage in three ground storage sites and two standpipes. With the extension of a pipeline by the Lower Colorado River Authority (LCRA), DSWSC contracted to purchase up to 1 million gallons a day of lake water. Almost all of its 45 miles of distribution pipelines are in a looped system to assure reliability and minimize disruptions. Dripping Springs Water has received a “superior” rating from the Texas Commission on Environmental Quality.

David McDaniel, SCADA Technician with CTWM explains “the Corporation wanted to be able to develop in real time and build and save their own status trends (featured below). Additionally, the historical viewer in Wonderware was very limited on its tag database.”

AJ Gray, Chief Operator, describes “some of the issues of our old system are you could not build or save trends and our [past] integrator told us that Wonderware was not coming out with a Windows 7 version and he offered no other solutions. We started looking at other software, but we could not get enough information about the products. Then when CTWM came out and showed us a live version and the ease-of- use, we were sold on VTScada and CTWM. We could not get a presentation of it like we got with CTWM.” “We can now handle totaling the flow meters inside VTScada with the analog statistics tag. This has saved us from having to call an integrator to reprogram the PLC code. Building and saving our own trends to review what has been going on in the system is something we could never do before and is a great surprise on how easy it was to get data into a trend for review. Also, the data that I am getting for my totals is coming in more accurate than before and we are very pleased with that.”

McDaniel explains the efficiency benefits: “VTScada helps DSWSC increase efficiency by being able to access the data by simply clicking on an object and getting a trend immediately, which is a huge time saver. Prior to VTScada [their integrator] would have to go into development, build the trend and then switch back to runtime to see the result. They couldn’t even save that trend. Their totals are more accurate to the totals they were seeing in the field so that means fewer trips out to meters for operators.”

The final system is comprised of one computer that monitors and controls all seven of their sites and does data collection for the flow meters. They use a combination of Modicon 612/00 PLC and ScadaPack 334 which also uses a data concentrator for polling remote PLCs. Communications are handled via an MDS radio network over a serial protocol. “Installation began April 15, 2015, and took only 14 days to complete.” McDaniel states.

Plans for the future are to eliminate the data concentrator and poll each site individually. “We will be adding some more sites and PLCs soon and might expand to include a Thin Client for the main office.”

About Central Texas Water Maintenance: With over 30 years of systems expertise and solid industry experience, CTWM stands ready to provide fast, friendly and dependable service. CTWM is proud to be a high-tech SCADA solutions specialist, providing technical SCADA automation and integration services for the water and wastewater industries. CTWM has completed over 15 VTScada applications. Owner, Ben Gray, says “The power you have with VTScada, whether you are using Ethernet, Serial or whatever, it is no problem with VTScada. VTScada is just so flexible, works with so many manufacturers that it is no problem using it on any project.”

| Try It For Yourself Download the 90-day Trial |

For More Details David McDaniel 512.243.2281 |

Images used with permission.