Toyota demonstrated how to select key performance indicators (KPIs) among many datapoints available among devices and systems connecting to supervisory control and data acquisition (SCADA) software, at ScadaFest 2024. See three elements of the Toyota Production System (TPS) and six requirements for SCADA software selection.

Written By Mark T. Hoske for Control Engineering

Courtesy: Mark T. Hoske, Control Engineering, skewed for better viewing

Learning Objectives

- Understand how resource constraints apply to electric vehicle battery resources and sustainability impacts

- Learn how three steps of applying Toyota Production System (TPS) processes were applied to select supervisory control and data acquisition (SCADA) software, effective software use and six requirements for product selection..

- Observe how to apply TPS to the full scope of processes to effectively set key performance indicators (KPIs).

Toyota SCADA software implementation insights

- Resource constraints apply to electric vehicle battery resources and sustainability and can change how we think about environmental benefits until EV batteries are more readily available.

- Three steps of applying Toyota Production System (TPS) processes were applied to select supervisory control and data acquisition (SCADA) software, effective software use and six requirements for product selection.

- Apply TPS to the full scope of processes to effectively set key performance indicators (KPIs).

Toyota is expanding use of supervisory control and data acquisition (SCADA) software to measure quality and sustainability metrics, among other areas, according to a ScadaFest case study from Jesse Daniels, engineering manager-maintenance and spare parts new model, Toyota Motor North America (Figure 1). The case study, “How Toyota determines key performance indicators in a sea of datapoints,” was part of the 2024 ScadaFest from VTScada by Trihedral, a Delta Group company. Daniels said Toyota has used VTScada software for 23 years in Georgetown, Kentucky, and plans to expand its use to all North American facilities. Daniels, with the company for 10 years, has background in biosystems and agriculture and has worked on Toyota’s sustainability measurements.

Figure 1: Jesse Daniels, engineering manager-maintenance and spare parts new model, Toyota Motor North America, said Toyota has used VTScada for 23 years in Georgetown, Ohio, and plans to expand use in all North American facilities. Daniels was among case study presenters at the 2024 ScadaFest, where discussions focused on more effective use of VTScada by Trihedral, a Delta Group company. Courtesy: Mark T. Hoske, Control Engineering

Battery resources for electric vehicles versus sustainability impacts

Toyota, 65 years in North America, employs 64,000 in U.S., Canada and Mexico, Daniels said, adding that because of the company’s size “we’re good at breaking software.” A Toyota battery plant, with investment of $5.9 billion, will employ 2,100 to make batteries for hybrid electric vehicles (HEV) and battery electric vehicles (BEVs) with full operations expected in 2025.

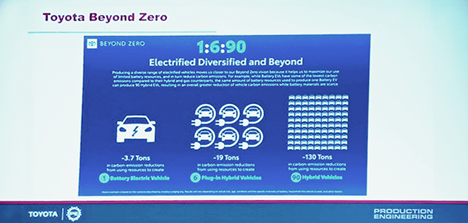

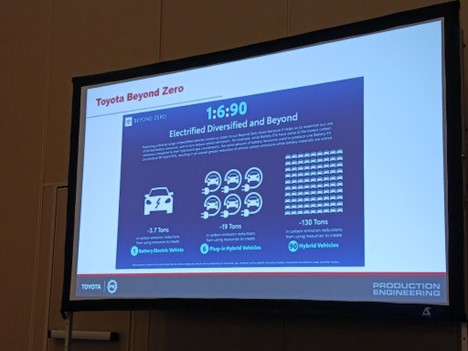

Using a Toyota Beyond Zero graphic (Figure 2), Daniels said while battery resources are contrained, the widest environmental improvements can be made with hybrid vehicles, above plug-in hybrids and battery only electric vehicles (BEV) using a 1:6:90 ratio. Battery resources for one BEV produces 3.7 tons of carbon emissions also could be used for six plug-in hybrids for 19 tons of carbon-emission reduction or 90 hybrid vehicles for 130 tons of carbon-emission reduction, Daniels said. The company has 26 electric options available at the time of the presentation, he said.

Figure 2: When electric vehicle battery resources are constrained, hybrid EVs provide the most environmental benefits, plug-in hybrid EVs next and plug-in EVs last, using a “Toyota Beyond Zero” calculation, said Jesse Daniels, engineering manager-maintenance and spare parts new model, Toyota Motor North America, at the 2024 ScadaFest, by Trihedral, a Delta Group company. Courtesy: Mark T. Hoske, Control Engineering

The Toyota Production Engineering and Manufacturing Center (PEMC) department in Georgetown looks at environment, sustainability, new technologies, diversity, improvements and engineers. Nearly 2,000 engineers evaluate safety and feasibility of mass production, digitalization, design, what equipment is used, reuse of equipment, equipment modifications, partners for design and building production equipment, testing and troubleshooting with manufacturing software and equipment. The department also looks at new and existing technologies to improve products, processes and methods.

Standardizing from 15 SCADA software applications to one

Standardization is a consideration in driving adoption of the best business process, technology and vendors. Planning, operations and products are considered to provide customer support with reliability and at lowest cost.

Key performance indicators (KPIs) are shown in dashboards. In North America, more than 15 applications were used to view and control utilities.

Applying Toyota Production System (TPS) processes: Three steps

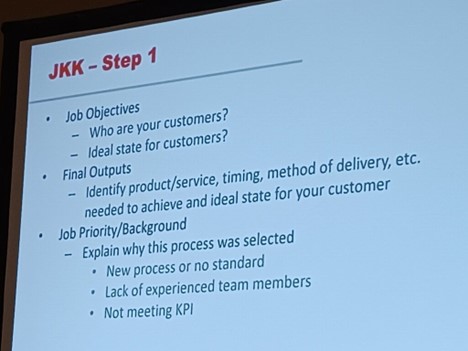

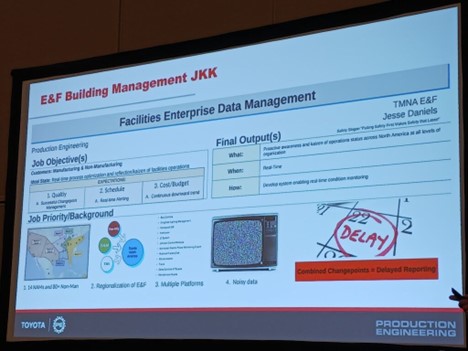

JKK stands for Ji Kotei Kanketsu, automation with the human touch, part of the Toyota Production System. JKK reinforces the ability to not produce bad quality products (waste) and prevent reoccurrence (Figure 3). JKK identifies job objectives and outputs, develops and optimal work process and establishes the developed process. Jidoka has origins in JKK and includes visual controls to identify problems, without passing defective components to the next process by understanding working elements. Just-in-time philosophy delivers products when needed and required.

Figure 3: JKK stands for Ji Kotei Kanketsu, automation with the human touch, part of the Toyota Production System, which reinforces the ability to not produce bad quality products (waste) and prevents reoccurrence. JKK originated with Sakichi Toyoda. JKK identifies job objectives and outputs, considering job priority and background in the first step, said Jesse Daniels, engineering manager-maintenance and spare parts new model, Toyota Motor North America, at the 2024 ScadaFest, by Trihedral, a Delta Group company. Courtesy: Mark T. Hoske, Control Engineering

Toyota Production System (TPS) processes are a company strength, Daniels said. TPS has three steps, to:

- Create job objectives, final outputs and job priority with background. Processes are independent of people and generally have four to five steps, explaining who does what and when.

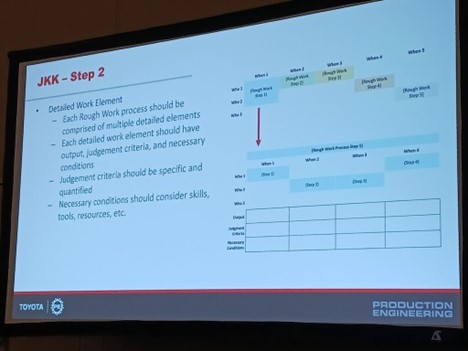

- Detail work elements for each step with judgement criteria and necessary conditions that should be considered, along with skills, tools, resources, etc. (Figure 4)

- Establish the process establishment, which is most difficult, requiring documentation, visualization, sustainment of standard work processes, with explanation of what events will trigger the need to revise.

Figure 4: Ji Kotei Kanketsu (JKK), automation with the human touch, is part of the Toyota Production System. In step two of JKK, define detailed work elements with multiples with outputs, specific and quantified judgement criteria and consider skills, tools and resources, said Jesse Daniels, engineering manager-maintenance and spare parts new model, Toyota Motor North America, at the 2024 ScadaFest, by Trihedral, a Delta Group company. Courtesy: Mark T. Hoske, Control Engineering

Tips for effective use of SCADA software

To effectively expand SCADA software’s for environmental and facilities (E&F) (Figure 5), Daniels said team efforts include the following areas for optimal work process development:

Operations, meeting, data storage, data optimization, real-visual management, reporting, reflection and analysis and Kaizen. Areas between operations and Kaizen require particular attention, he noted. For many areas, andons of various designs are used as visual control devices to display real-time process status.

For facilities enterprise data management, job objectives were set, including job priority and background. Final outputs included proactive awareness in real-time and system develop enabling real-time condition monitoring.

Among processes adjusted as a result was changing machine readiness when cars were not being built to drastically reduce or eliminate energy use, Daniels said.

Figure 5: More effective data management requires developing a system that enables real-time condition monitoring. Using multiple systems can add data noise and delay reporting, said Jesse Daniels, engineering manager-maintenance and spare parts new model, Toyota Motor North America, at the 2024 ScadaFest, by Trihedral, a Delta Group company. Courtesy: Mark T. Hoske, Control Engineering

Six requirements for product selection

Given use of SCADA within context of the Toyota Production System, six JKK requirements for product selection were: Functional requirements, non-functional requirements, total cost of ownership, timing, usability and sustainability.

Using a Toyota big data platform, a data lake will hold all data for global reference. Determine what data points matter, such as trip alarms, run status, power and efficiency, among others, he said.

Andons provide visual indication of production status (green, orange, yellow and red). A dashboard allows users to drill down for easier navigation and more details. A standard andon screen dashboard is provided, and operators can make changes to serve needs specific to their areas.

For monitoring equipment health, for instance, SCADA software screens can help investigate issues, troubleshoot and develop countermeasures. As more areas transfer from paper to digital workflows, the SCADA software implementation helps to show people possibilities for troubleshooting and shift turnover. A condition-based maintenance approach lets the equipment explain what is needed when, rather than scheduling, which could waste useful equipment life, time and resources by replacing components before replacements are needed.

The new software provides views of unique systems in unique buildings in the same HMI, providing the ability to “yokoten” processes among sites in short amount of time, that is, quickly compare challenges and develop solutions across sites, Daniels said.

Using a tank-farm screen, among multiple sites, Daniels talked through how the intuitive SCADA implementation created screens and connected them to equipment in four hours, adding that screens can be created without coding experience.

Implementations provide ability to visualize efficiency of non-production energy (NPE), in real time.

The paint department, identified among the largest energy users, can more effectively make changes to reduce consumption and help consider multiple goals, such as Industry 4.0 initiatives, costs and meeting environmental challenge 2050 targets. Daniels said the SCADA software implementation provides visibility needed to see progress toward meeting sustainability and other goals.

In an 18-month roll out to all plants, Daniels said a goal was to use the software to ensure visibility and consensus for users (as opposed to eliminate other software used at each site).

Understand the full scope of processes to effectively set KPIs

Summarizing (see video clip), Daniels covered the Toyota Environmental Challenge and other key points, explaining that the SCADA software implementation helps with measuring and ensuring progress toward targets using identified KPIs. Objectives and outputs must be clearly defined and understood so that the quality ownership process can be developed implemented and maintained.

Consistent reflection is part of the process, Daniels noted. He asked, “How can you set KPIs if you don’t understand the full scope?” Crediting an unnamed West Virginia co-worker, Daniels observed that a self-improving system continues evaluations because a system may be the best ever but not forever.

CONSIDER THIS

Do you re-examine processes to improve before (or as) you apply news software?

Mark T. Hoske is content manager, Control Engineering, CFE Media and Technology, mhoske@cfemedia.com.

Author Bio: Mark Hoske has been Control Engineering editor/content manager since 1994 and in a leadership role since 1999, covering all major areas: control systems, networking and information systems, control equipment and energy, and system integration, everything that comprises or facilitates the control loop. He has been writing about technology since 1987, writing professionally since 1982, and has a Bachelor of Science in Journalism degree from UW-Madison.