This is a legacy tag type. You are advised to use the I/O and Calculations Tag instead.

Use this legacy type only if you are certain that it contains unique features that are absolutely necessary to your work.

Counted towards your tag license limit.

It is the role of Analog Status tags to read analog data such as well level or a motor speed from an I/O device.

When dealing with analog values, PLCs are typically calibrated to provide a signal from zero to something, depending on the hardware. This may not correspond to the engineering units being measured. The values from the PLC might mean a range of 0 to 100%, -40°F to 451°F, or zero to 140 knots. You will configure your tags to adjust for this, providing the minimum and maximum values of raw, unscaled data from the equipment and the minimum and maximum values that this corresponds to the engineering units being measured. Scaling is always linear.

Values read by Analog Status tags are logged by default. New values are written on change, but not just any change. A deadband of one quarter of one percent (0.25%) of the scaled range of values is applied. Values must change by this much before a new one will be written to the Historian. Naturally, you have complete control over this and can configure any deadband value that you want.

Changes in value smaller than the Deadband setting will not be logged! Always check the settings in the Historian tab.

Analog Status tags will apply a default deadband of 1/4 of one percent of your display scale. (DefaultAnalogDeadbandFractionOfFullScale)

Read about the deadband in the section for the Historian Tab. Do not risk either a value so low that it logs system noise or a value so high that important information is lost.

The ID tab of every tag includes the same common elements: Name, Area, Description, and Help ID.

Name:

Uniquely identifies each tag in the application. If the tag is a child of another, the parent names will be displayed in a separate area before the name field.

You may right-click on the tag's name to add or remove a conditional start expression.

Area

The area field is used to group similar tags together. By defining an area, you make it possible to:

- Filter for particular tag groups when searching in the tag browser

- Link dial-out alarm rosters to Alarm tags having a particular area

- Limit the number of tags loaded upon startup.

- Filter the alarm display to show only certain areas.

- Filter tag selection by area when building reports

When working with Parent-Child tag structures, the area property of all child tags will automatically match the configured area of a parent. Naturally, you can change any tag's area as required. In the case of a child tag, the field background will turn yellow to indicate that you have applied an override. (Orange in the case of user-defined types. Refer to Configuration Field Colors)

To use the area field effectively, you might consider setting the same Area for each I/O driver and its related I/O tags to group all the tags representing the equipment processes installed at each I/O device. You might also consider naming the Area property for the physical location of the tag (i.e. a station or name of a landmark near the location of the I/O device). For serial port or Roster tags, you might configure the Area property according to the purpose of each tag, such as System or Communications.

You may define as many areas as you wish and you may leave the area blank for some tags (note that for Modem tags that are to be used with the Alarm Notification System, it is actually required that the area field be left blank).

To define a new area, type the name in the field. It will immediately be added. To use an existing area, use the drop-down list feature. Re-typing an existing area name is not recommended since a typo or misspelling will result in a second area being created.

There is no tool to remove an area name from VTScada since such a tool is unnecessary. An area definition will exist as long as any tag uses it and will stop existing when no tag uses it (following the next re-start).

Description

Tag names tend to be brief. The description field provides a way to give each tag a human-friendly note describing its purpose. While not mandatory, the description is highly recommended.

Tag descriptions are displayed in the tag browser, in the list of tags to be selected for a report and also on-screen when the operator holds the pointer over the tag’s widget. For installations that use the Alarm Notification System, the description will be spoken when identifying the tag that caused the alarm.

The description field will store up to 65,500 characters, but this will exceed the practical limits of what can be displayed on-screen.

This note is relevant only to those with a multilingual user interface:

When editing any textual parameter (description, area, engineering units...) always work in the phrase editor. Any changes made directly to the textual parameter will result in a new phrase being created rather than the existing phrase being changed.

In a unilingual application this makes no difference, but in a multilingual application it is regarded as poor practice.

Help Search Key

Used only by those who have created their own CHM-format context sensitive help files to accompany their application.

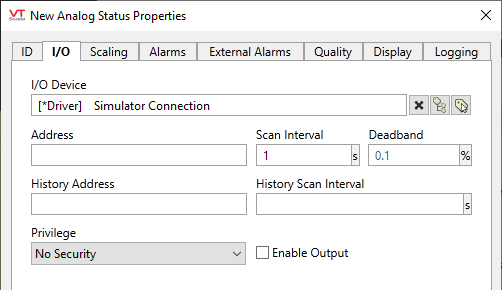

Analog Status properties I/O tab

The I/O Tab includes properties used to identify and establish a connection to the communication driver tag being used to exchange data with your physical I/O device (e.g. PLC or RTU), or to the polling driver responsible for determining the order and rate at which data polls will occur.

I/O configuration of an Analog Status tag

I/O Device

Select the communication driver tag from which data will be read.

By default, the tag will look for an ancestor or sibling tag that is a device driver (*Driver). If none is found, the text "--Missing--" will be displayed. If more than one equally qualified tags are found, "--Error: Multiple Drivers--" will be displayed. The tag button to the right of the field opens the tag browser, from which you can either select an existing communication driver tag or add a new one. The X button will clear the field. Right-clicking on a tag in the field will open a dialog with which you can add or remove a Snapshot Expression or open a selected driver's properties dialog.

Address

Provide the address within the I/O device from which this tag is to read data. This value must match the configuration of your PLC or RTU hardware. Refer to the Addressing topic for your particular device driver for guidance.

If a Write Address is provided the Read Address is used only as feedback and will set the value of the tag regardless of the value written. If the value in the Read Address does not match the value written then the tag's Mismatch flag is set to true and will be reflected in linked widgets, either as a blink or a mismatch color, according to the widget.

Address Assist: (...)

Several drivers including SNMP, OPC Classic Client, Fisher ROC and others, provide an Address Assist button to help you. The content of the Address Assist dialog will vary according to the driver.

Scan Interval

Provide the frequency, measured in seconds, at which the I/O device should be scanned for new data. Reduce system load by setting this as high as possible, as appropriate for the equipment being monitored. If the I/O Device is a Polling driver, which provides its own scan interval, then this field will not accept data. Otherwise, try to keep scan intervals the same, so far as is reasonable, so that drivers can group (coalesce) reads from equipment where you have sequential addresses.

Deadband (On data reading, for Analog values only)

If defined, the value on the device must change by more than this amount before the tag will register it as a new value. A deadband can greatly improve application efficiency by filtering out noise and eliminating unnecessary work to process that noise as if it were useful data.

The deadband is an absolute value, not a percentage, and is specified in terms of the tag's display values if set or the scaled engineering units otherwise. (Refer to notes for the Scaling tab.) If a deadband value is not provided, one will be calculated automatically based on several factors including the logging deadband and the application property, DefaultDriverDeadbandFractionOfFullScale.

See also: Deadbands for Reading and Logging

History Address

If set, then the address field becomes optional. This field provides a means of reading values as recorded by a data logger.

If both the address and the history address are provided, then the address will be polled for data at the interval set by the Scan Rate, but the values read from the data logger will overwrite the values logged by this tag when it is updated.

The form for the history address will depend on the RTU. Please refer to the addressing reference chapter for your driver.

Note that it is not possible to enter a parameter expression directly in the History Address field. As an alternative, you may enter compound address in the Address field using a parameter expression. For example, if Addr, HistAddr and HistoryRate are all properties of a parent tag, the following expression in the Address field will create a compound address with all three components:

concat(.\Addr , "):(" , .\HistAddr , "):(" , .\HistoryRate )

The characters "):(" separate each component of the address. Do not add a leading or trailing parenthesis around the entire expression.

Further information on reading history information can be found in the topic SCADAPack History Read

History Scan Interval

Sets the time between polls of the history data logger. If a History address has been set, but this field is left blank, then it will default to the value set in the Scan Rate field. The recommended value for this field is 60 seconds. Lesser values may cause communications to slow down.

Note that it is not possible to enter a parameter expression directly in the History Scan Interval field.

Privilege

Select a custom security privilege

Enable Output

This privilege has been moved from Quality tab to the I/O tab. If checked, this input tag may also be used to write data to the specified address of the communication driver. A Security Privilege may be set in the Quality tab to restrict access to this feature.

Publisher

Select a Publisher tag if one is required for your configuration. Defaults to [*Publisher]. Eligible tags (Publisher tags that are a direct ancestor, uncle or sibling) will automatically link or you can select a tag manually. VTScada publishing configurations may include:

- An OPC client when your application has a properly-configured OPC Classic Server Setup tag.

- A Sparkplug B Edge Node or a Sparkplug B Edge Device.

- A MultiSpeak interface if properly configure. See: MultiSpeak Support.

- A Data Diode publisher or client tag.

Publish

This tag will publish data if a publisher is configured and this setting is enabled. If this setting is disabled, the tag will stop publishing data.

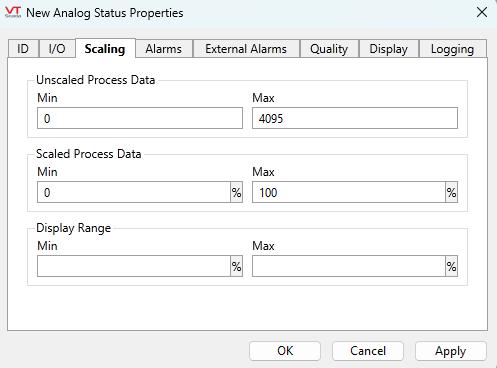

Analog Status properties Scaling tab

The Scaling Tab requires values that will be used to convert unscaled, raw data from the I/O device associated with this tag into scaled data that will be reported to operators.

Changes in value smaller than the Deadband setting will not be logged! Always check the settings in the Historian tab.

Analog Status tags will apply a default deadband of 1/4 of one percent of your display scale. (DefaultAnalogDeadbandFractionOfFullScale)

Read about the deadband in the section for the Historian Tab. Do not risk either a value so low that it logs system noise or a value so high that important information is lost.

Analogs can read text values if those are returned by the driver. Set the first four of the scaling parameters to "1" in order for the tag to interpret data as text.

Better is to use the String I/O tag for reading text data to avoid problems when attempting to mix text and numbers. A text "2" sent to an Analog Status with scaling set to 1 will be scaled to 1.

The first four fields on this tab affect the tag's value, scaling it from the input range to a desired output range.

The default value for each of these fields is stored in an application property. You are advised to change those properties to match the values used by your hardware by using the Edit Properties page of the Application Configuration dialog. You will need to use the Advanced mode of the properties page. The properties to copy and edit are:

- AnalogUnscaledMinDefault

- AnalogUnscaledMaxDefault

- AnalogScaledMinDefault

- AnalogScaledMaxDefault

|

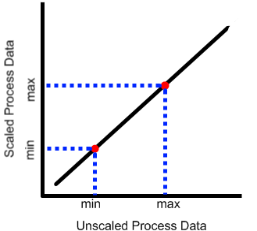

VTScada assumes a linear relationship between the values as shown. The scaled and unscaled process values you provide set the slope of the line, allowing any value on one axis to be mapped to the other. The values do not limit what the tag can read, but the Scaled Process Min and Max values do limit what the tag can write. |

Min and Max Unscaled Process Data (Required.)

Use these to tell VTScada the range of raw values to expect from or write to hardware.

Min and Max Scaled Process Data (Required.)

These values must match the Unscaled Min and Max values. VTScada uses them to convert between the engineering units shown in the SCADA system and the raw values read from or written to the hardware. By default, the "Limit outputs to within Scaled min/max" option is selected. If you deselect this option, the output range limit is disabled. This allows any value, including negative integers, to be sent to the tag. However, scaling is still applied to the new output value, regardless of the value sent to the tag.

Display Range Min and Max (Optional.)

These two fields have no effect on the value of the tag.

Set the Min and Max Display Range values to define the default scale range for the HDV trend view and certain widgets, such as the various meters. Use these when values are expected to stay within a portion of the full scale range and it is therefore helpful to adjust the displayed range as needed.

If left blank, the Scaled Process Data Min and Max values will be used as the Display Range values.

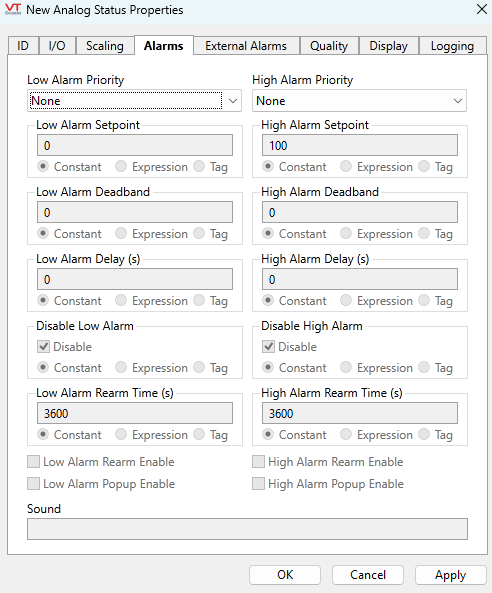

Analog Status properties Alarms tab

The Alarms tab contains two (optional) built-in alarms. One is for a high set point and one for a low set point, based on the value of this tag. The initial priority for each is "None", preventing unconfigured alarms from being counted as disabled alarms.

While the priority is set to "None" all other controls are disabled.

The following includes descriptions of features found in the Advanced version of this tab.

Alarm Priority

The Alarm Priority drop-down list enables you to select the priority of the alarm that will be triggered for this tag if its value passes the value defined for the setpoint. The available priorities are:

- None

- 0 - Event

- 1 - Critical Alarm

- 2 - High Alarm

- 3 - Warning Alarm

- 4 - Notice Alarm

If you have defined your own Alarm Priority tags, those will also be available for selection.

Alarm Setpoint

The Alarm Setpoint field enables you to enter the value, beyond which an alarm will be triggered. The source for this field may be a constant, the result of an expression, or the value of a tag.

Alarm Deadband

If noise in the system causes a value to fluctuate above and below the set point, the alarm will repeatedly switch between active and inactive status. By using the deadband, you can avoid filling the alarm history with these events by setting an amount by which the tag’s value return to the normal state before it is considered to no longer be active. The deadband is used only for changing a current alarm’s active status. It does not affect the set point.

Alarm Delay

Spikes in the value being monitored may cause transient alarms. By setting an alarm delay, you can specify that the trigger condition must remain true for a given length of time before the alarm is considered to have occurred.

Disable Alarm

The Disable Alarm field enables you to specify whether the alarm for this tag is disabled or enabled. Disabling of alarms is typically used in situations where you wish to avoid false alarms. For example, in the event that routine maintenance is being performed on the equipment represented by this tag, or when you are aware that another interruption in communications will occur for a period of time. In such situations, the alarm can be disabled until the maintenance is complete and communications are reestablished.

A value of 0 (or any tag or expression that returns 0) means that the alarm has not been disabled. Any value other than 0 in this field indicates that the alarm has been disabled.

The following is an advanced configuration technique. If you do not need to toggle alarm disabling on hundreds of alarms on a frequent basis, this technique is not appropriate for your application.

Each time you toggle an alarm between enabled and disabled, an event is recorded. If you must repeat this operation frequently for hundreds of tags, a large number of events can be recorded.

As an alternative, you could create a non-optimized expression for the alarm setpoint that toggles between the real setpoint and one that is either so high or so low that it can never cause the alarm to trigger. Changes made to the setpoint this way do not result in events being recorded.

Alarm Rearm Time

Applies only if Alarm Rearm Enable is selected for this alarm. If the alarm has been acknowledged, but remains active for the time shown in this field, the alarm will return to the unacknowledged state. Audible and visible warnings configured for this alarm’s priority level, will again be displayed. The Alarm Rearm Time is measured in seconds, and defaults to 3600 (1 hour). The value in this field must be greater than 0.

Alarm Rearm Enable

Controls whether this alarm will revert back to an unacknowledged state if it remains active for the length of time set in Alarm Rearm Time, after having been acknowledged by the operator.

Alarm Pop-up Enable

If the configuration variable AlarmPopupsEnable is set to 1, then setting either the Alarm Pop-up Enable will result in a pop-up dialog being displayed whenever the respective alarm is triggered. It is suggested that this feature be used sparingly.

Sound

The Sound field can be set to blank, 0, 1, or to the name of a .WAV sound file to be played.

If 0, no sound will be played when this alarm is triggered.

If blank or 1, an alarm sound whose properties are configured on the associated Alarm Priority tag will be played.

If the name of a .WAV sound file, it will override any alarm sound configured for the associated Alarm Priority tag. If the specified sound file is not found, the alarm will revert to using tones as specified in the associated Alarm Priority tag.

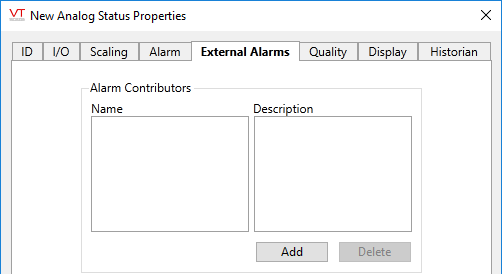

Analog Status properties External Alarms tab

Use the Add button to create new external Alarm tags and the Delete button to remove them. The new alarm tags will be created as children of the current tag.

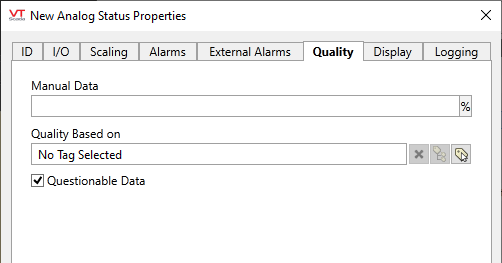

Analog Status properties Quality tab

Manual Data

Sets a constant value that will be used instead of live data. Use when testing a new tag if you need to check behavior when a value is outside the normal operating range. Tags that have manual data are marked by a flashing exclamation mark within any linked widgets. Logged values are marked with an exclamation. Always reset this to blank after testing.

Quality Based On

The Quality Based On field can be tied to a driver tag, a tag that monitors driver communication errors, a register in the PLC or RTU, or any other indication of system health. The tag you are configuring will use that value to set an internal variable named QualityIssue. You may test this value in an expression: [TagName]\QualityIssue.

QualityIssue will be a 0 or 1 where "Good Quality" is defined as a value of "0 or Invalid" and "Bad Quality" is defined as any valid, non-zero value. This is consistent with driver communication error values.

Widgets that use the System Style tag will display bad quality using the color set on the Exceptions tab.

The Quality Based On field can also be used when this tag is to be a contributor to a custom-built container tag. Please see the topic, Merit tab and Quality tab, for details.

Questionable Data

Use the Questionable Data parameter to flag this tag’s data in the event that you suspect the values it is reporting might not be accurate, or when this tag has initially been created and you wish to ensure that its data is marked for extra monitoring.

Analog Status properties Display tab

Style

When this tag is represented on screen by widgets that can use a Style Settings tag, you can save development time by choosing the Style Settings tag that holds the correct display configuration for this tag instance. (See: Style Settings Tags)

The default configuration will search for the first ancestor or then sibling tag of the Style Settings type. If there is none, it will use System Style, which is the default style tag that is automatically part of every new VTScada application.

Display Order

Used to specify the placement of this tag when viewed in an associated station dialog. See Order tab for further details.

Engineering Units

Provide the units of measure that the scaled value represents. This text will be used by widgets that include engineering units as part of the display. Possible values for this field include "rpm", "degrees C", "%", etc.

You can add a degree symbol to the engineering units by holding down the Alt-key while typing 0176 on the numeric keypad. Release the Alt-key before typing the C or F.

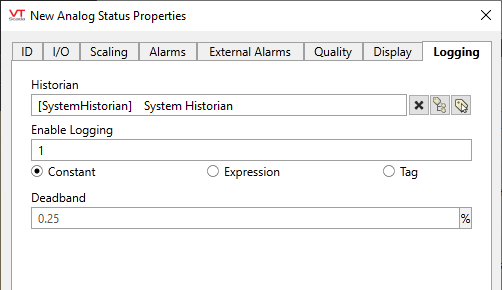

Analog Status properties Logging tab

Analog Status Logging tab

Read the label of the deadband setting on your tag! Values smaller than the deadband setting will not be written to the Historian.

Historian

If an Historian tag is selected, this tag's run-time values will be saved for use in reports and the Historical Data Viewer. Historian configuration and advanced logging options are described in the discussion of the Historian Tags.

If your goal is to disable logging, set the Enable parameter (below) to 0 rather than deleting the Historian parameter.

There are consequences if you change the selected Historian tag after you have begun collecting data. If you switch to a new Historian (perhaps for organizational or load sharing purposes), the data collected for this tag by the previous Historian will become inaccessible. Historian selection and configuration should be done during the project design stage.

Enable Logging

If values should be logged only while certain conditions are true, you can tie the Enable Logging option to any tag or expression that will change from zero (logging disabled) to non-zero (usually 1; logging enabled).

Deadband

The value of an Analog Status tag is automatically logged on change. The deadband range, specified in the defined engineering units, sets a minimum amount by which the tag's scaled(*) data must change before a new value is written to the log file. This will dampen out minor changes of value, reducing the size of the log file by excluding system noise.

If the deadband value is not set explicitly, the deadband will be the difference between the high and low display scale values (set on the Scaling tab), multiplied by the value of the application property, DefaultAnalogDeadbandFractionOfFullScale. That property defaults to one quarter of one percent (0.25 on a range of 100). Note that display scale values, if not set, default to the minimum and maximum scaled process data values.

No default will be applied to legacy applications. You may choose to set a value.

The following widgets are available to display information about your application’s Analog Status tags: